Understanding HASL (Hot Air Solder Leveling) in PCB Manufacturing: A Guide by Viasion Technology

In Printed Circuit Board (PCB) manufacturing, surface finishing processes play a critical role in ensuring the reliability, durability, and solderability of electronic components. One widely used surface finish is HASL, which stands for Hot Air Solder Leveling. Viasion Technology, a leader in electronic manufacturing services (EMS), provides valuable insights into HASL and its importance in PCB assembly processes. This blog aims to demystify HASL, explaining its benefits, applications, and Viasion Technology’s expertise in delivering high-quality PCB solutions.

What is HASL?

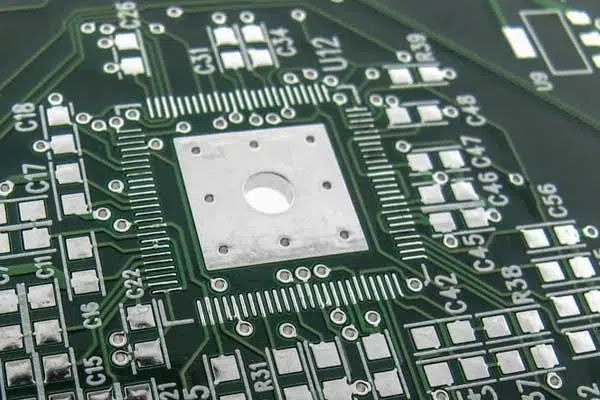

HASL, or Hot Air Solder Leveling, is a surface finishing technique used to coat the exposed copper surfaces of a PCB with a layer of molten solder. The process involves several key steps:

- Flux Application: Initially, a flux is applied to the bare copper PCB to remove oxidation and ensure proper solderability.

- Solder Bath: The PCB is then immersed in a bath of molten solder. The solder adheres to the exposed copper pads and traces, forming a uniform coating.

- Hot Air Leveling: After immersion, hot air is blown over the surface of the PCB to remove excess solder and achieve a smooth, level surface finish.

- Cooling and Solidification: Once levelled, the PCB is cooled to solidify the solder coating, creating a durable and solderable surface for mounting electronic components.

Benefits of HASL

HASL offers several advantages that make it a preferred choice for PCB surface finishing:

- Cost-Effectiveness: HASL is a cost-effective surface finishing method compared to alternatives like ENIG (Electroless Nickel Immersion Gold) or immersion silver, making it suitable for mass production.

- Good Solderability: The solder-coated surface of HASL PCBs provides excellent solderability, facilitating reliable and robust solder joints during component assembly.

- Suitability for Through-Hole Components: HASL is well-suited for through-hole component assembly due to its ability to coat PCB surfaces and through-holes with solder.

- Thermal and Electrical Conductivity: The solder coating enhances thermal and electrical conductivity, improving electronic circuits' overall performance and reliability.

Applications of HASL

HASL finds widespread use across various industries and applications, including:

- Consumer Electronics: HASL cost-effectiveness and reliability benefit PCBs for smartphones, tablets, televisions, and other consumer devices.

- Industrial Electronics: PCBs in industrial automation, control systems, and power electronics leverage HASL’s robust solderability and durability.

- Automotive Electronics: HASL-coated PCBs are utilized in automotive applications, including engine control modules, infotainment systems, and sensor assemblies.

- Telecommunications: Communication equipment, networking devices, and satellite systems rely on HASL for dependable solder joints and performance.

Viasion Technology’s Expertise in HASL

Viasion Technology distinguishes itself in PCB manufacturing with advanced HASL capabilities:

- Quality Assurance: Viasion Technology follows stringent standards (ISO 9001) to ensure consistent and reliable HASL surface finishes that meet industry specifications and client requirements.

- Customization: Offering customizable HASL solutions tailored to specific PCB designs, sizes, and applications, ensuring optimal performance and reliability in diverse operating environments.

- Environmental Responsibility: To minimize environmental impact, implementing eco-friendly practices in HASL processes, including waste reduction and compliance with environmental regulations.

Conclusion

In conclusion, HASL (Hot Air Solder Leveling) is a vital surface finishing technique in PCB manufacturing, offering cost-effective, reliable, and solderable surfaces for electronic components. Viasion Technology’s expertise in HASL ensures high-quality PCB solutions that meet the stringent demands of modern electronics applications. HASL plays a crucial role in enhancing electronic products' performance, reliability, and longevity, whether for consumer electronics, automotive systems, industrial automation, or telecommunications.

For businesses seeking reliable and efficient PCB manufacturing solutions, Viasion Technology provides a trusted partnership built on innovation, quality, and customer satisfaction. Partner with Viasion Technology and leverage the advantages of HASL for your next electronic manufacturing project.

Comments

Post a Comment